Assaying is a process of determining proportions of precious metal, in ores and metallurgical products.

XRF TESTING

Our team utilizes state of the art XRF (Handheld X-Ray) Spectrometers to get an initial reading on the purity of your lot.

Though XRF readings are usually highly accurate, there are many lots that contain precious metal plates or are heavily mixed with other metals, which is why we always conduct a full Fire or

Ultrasound Assay (depending on the metal in question) to confirm our readings.

Additionally, if your lot contains Gold, we will use an Acid Test to gauge its purity.

By utilizing XRF or Acid Testing and Fire or Ultrasound Assaying in combination with one another, we can get the most accurate reading on your lot’s total purity, which can greatly increase the value of your lot!

ACID TESTING

Precious metals are inherently inert, which means that they are resistant to chemicals, whether it’s acid, oxidation, or corrosion.

Generally, acid testing is utilized for assaying gold lots. It involves testing the mineral’s streak on a stone with various concentrations of nitric acid.

We rub the precious metal sample on a touchstone and treat it with a low concentration of nitric acid. If the metal dissolves in the acid, it’s unlikely to contain gold. If any the metal does not dissolve, we check for the level of reaction that occurs, which can allow us to determine the approximate purity of your gold!

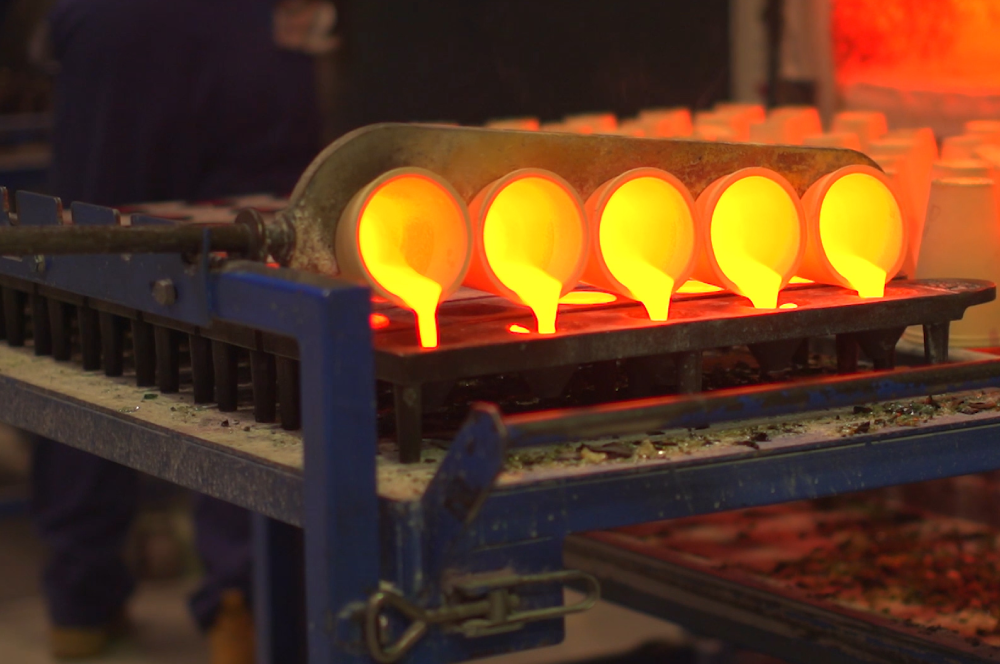

FIRE ASSAY

Fire assay is the final testing method we utilize as it requires the melting of the lot.

We start by mixing a sample of your precious metal lot with a fluxing agent. The fluxing agent reduces the melting point of the precious metal and works to remove any impurities present in the sample.

Fire assay is the final testing method we utilize as it requires the melting of the lot. We start by mixing a sample of your precious metal lot with a fluxing agent. The fluxing agent reduces the melting point of the precious metal and works to remove any impurities present in the sample. Then a collecting agent, generally nickel or lead, gets added. This lead or nickel acts as a collector and gets deposited at the crucible base as a bead that generally gets extracted from the crucible at the end of the process.

If we use the bead as a collecting agent, the lead bead gets absorbed into the furnace’s cupel, and the precious metal content of the lot gets left behind. As one of the top refineries in New York, we utilize modern, highly-efficient equipment with the latest technology to ensure that our assaying process is executed with the utmost precision.